Chemical Spraying

Orchard Foliar Spray Trials

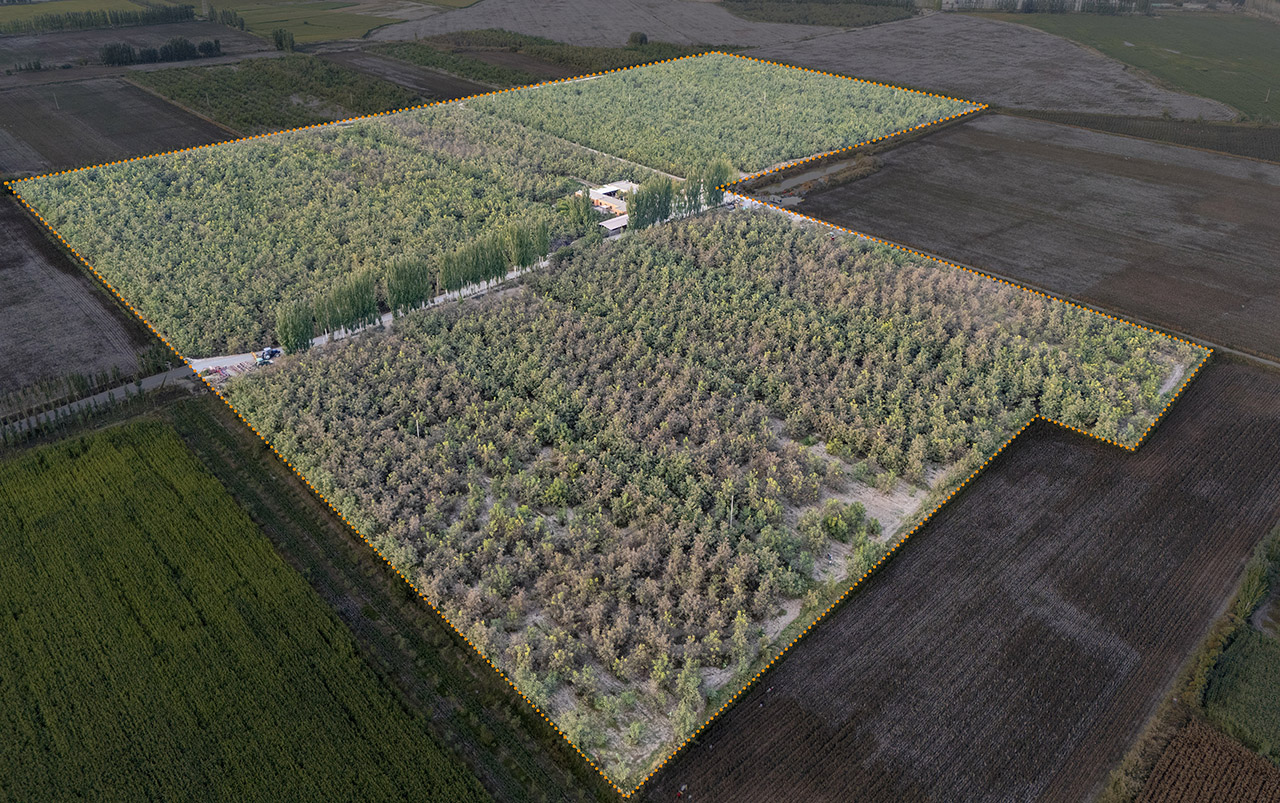

Xinjiang is renowned for its premium fruit and expansive orchards—ideal proving grounds for Shitian Aviation’s aerial spraying solutions. During peak harvest season, our team conducted comparative trials using clean water in place of chemicals and mounted two different spraying systems to evaluate which configuration best meets orchard needs.

Test block: 18.87 hectares total area covered in 30 minutes (single sortie, full coverage).

Test Setup

- Objective: Compare droplet formation, canopy penetration, and visible coverage between two aerial spray devices.

- Medium: Clean water (for visibility and consistency).

- Environment: Late-afternoon/evening trials across similar orchard rows to control for wind and canopy variability.

Solution A: Dual-nozzle system producing 10–20 μm droplets for ultra-fine coverage.

Solution A close-up: micro-droplet plume and canopy wetting pattern.

Solution B: Standard boom sprayer with 12 nozzles (6 per side), up to 8 L/min total flow.

Visual Results

Solution B animation: clear lateral spread and consistent row-to-row coverage.

Solution B animation: canopy engagement and visible leaf wetting across crown.

Key Findings

- Coverage & Visibility: Solution B demonstrated highly visible, uniform coverage under favorable lighting, aiding operator verification in real time.

- Droplet Characteristics: Solution A’s 10–20 μm droplets favor fine misting and potential canopy penetration, but were harder to document visually due to suboptimal light and wind during its run.

- Throughput: With up to 8 L/min flow, Solution B achieved rapid, even wetting—well-suited for foliar nutrients and contact agents when visual confirmation is critical.

- Operational Efficiency: Completing 283 mu in 30 minutes shows strong potential for large-scale orchard operations with minimal turnaround.

Operational Considerations

- Lighting & Wind: Late-day light significantly impacted footage clarity. Schedule verification passes during consistent illumination; log wind speed to normalize comparisons.

- Nozzle Selection: Match droplet size to task—ultra-fine (Solution A) for penetration and systemic uptake; standard boom (Solution B) for uniform visible leaf wetting and contact efficacy.

- Rate & Speed Tuning: Calibrate flight speed, altitude, and flow to canopy height and row spacing to reduce drift and optimize deposition.

Overall, both systems have merit: Solution A for fine, penetrating mists under stable conditions; Solution B for high-throughput, clearly verifiable coverage. Future trials will incorporate tracer dyes and deposition cards to quantitatively compare leaf-surface deposition, underside wetting, and penetration across canopy layers.